An introduction to working a metal after casting

- Oct 10, 2022

- 3 min read

Updated: Oct 22, 2022

Why do we work after casting?

While cast materials may not have the final shape wanted, the microstructures may also need working to optimize the properties of the final product. Two common issues are:

Chemical segregation

Separation of constituent elements during casting can lead to fast corrosion, softer materials, and embrittlement.

Coarse microstructures

A coarse microstructure leads to a softer, less wear-resistant material and issues such as "orange peel."

Working after casting is done to refine the shape of the final product (e.g., starting from an ingot, wire, plate, rod, etc.) and the overall microstructure.

Preparation

Before working with ingot materials, we often need to grind off surface defects and crop off the top of the ingot containing the pipe to prevent defects such as surface cracks, oxide/slag inclusions, internal cracking, and porosity from developing.

Hot working or cold working?

For precious metals, cold working refers to deforming at room temperature since room temperature for each of our four precious metals (silver, gold, palladium, and platinum) is relatively cool compared to their melting temperatures. Deformation occurs by slip, which involves the generation and motion of dislocations. As we deform further, we introduce more dislocations that impede one another, increasing yield strength and hardness but reducing further ductility. Ultimately, the material will crack.

Hot working is typically done at temperatures above half the melting temperature (in absolute degrees kelvin) of the alloy. Hence the working temperature is specific to each alloy. If we work a metal when it is hot, the temperature is high enough for the recrystallization to occur during deformation. The dislocations generated from deformation are 'annealed" out just as quickly. This means we preserve the "soft annealed" condition, which can be repeatedly worked before cracking, without any increase in strength or hardness. Metallurgists call this "dynamic recrystallization".

Cold-working metal is performed at ambient temperature. It is typically performed to impart additional hardness, improved strength, and a more accurate shape and superior surface. As the temperature is low, recrystallization doesn't occur. The metal becomes harder, and it must be annealed from time to time to avoid overworking.

Microstructure and working: A wedding band case-study

When a wedding band is rolled and deformed (upset), not all parts of the metal experience the same force, and so the microstructure is not the same throughout the cross-section. It is heterogeneous.

Deformation typically occurs the most at the surface, and so the grains and microstructure will be most heavily deformed here. This means the surface will be more brittle, and cracking is often likely to start at the ,surface.

When we subsequently anneal, the fibrous-like grain structure is disrupted by equiaxed (round) recrystallized grains.

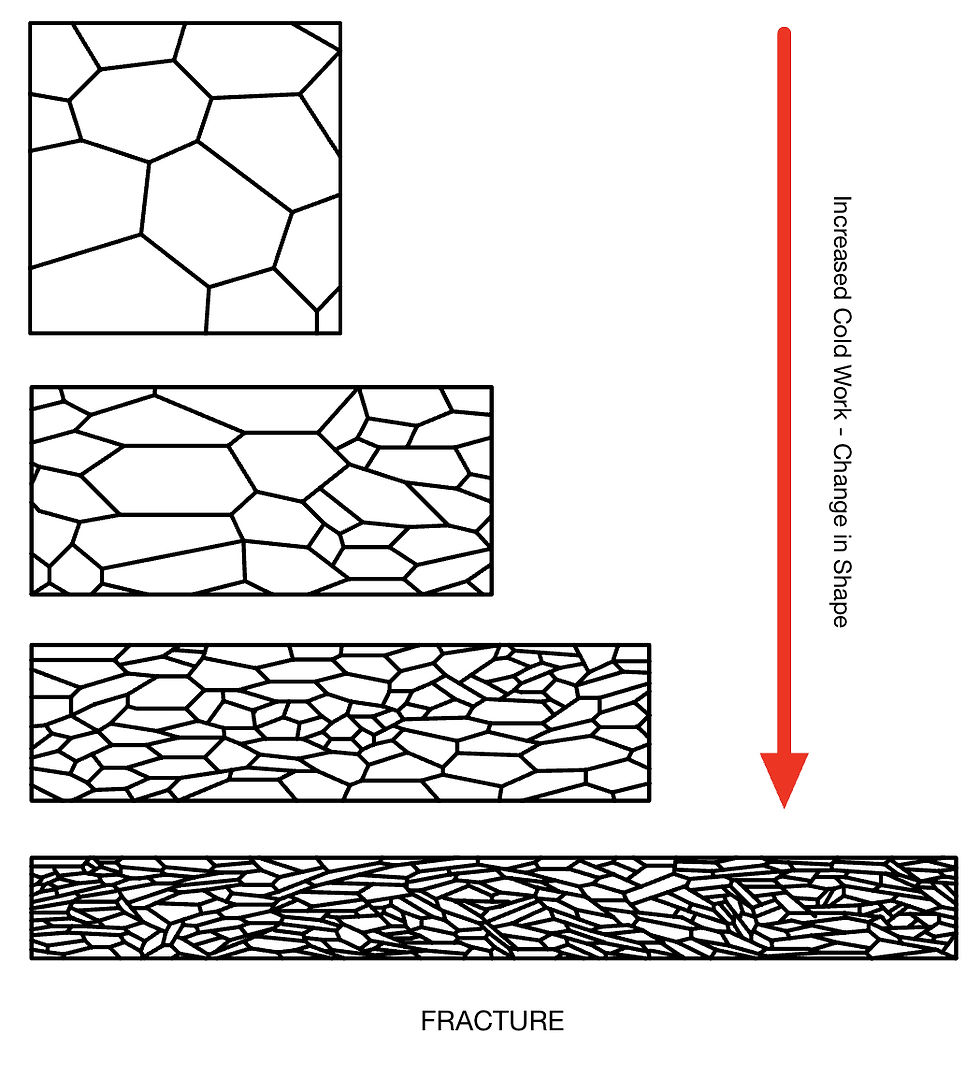

Overworking and microstructure

If we repeatedly work a metal without annealing or working in the "hot" state, then the material will become harder and more brittle. If we overwork a material, it can crack or fracture.

To avoid overworking in the cold state, we subsequently anneal. The resulting grain size after annealing depends on the amount of cold work, the annealing temperature, and time:

More cold working leads to finer grain size

Annealing for longer and at higher temperatures leads to a larger final grain size

To avoid too large a grain size, it is recommended to anneal only after substantial cold work (e.g. a 60% reduction in thickness). For a given sample, the desired annealing period varies with temperature and annealing time after cold work.

Should I hot work or cold work my alloy?

There are many advantages and disadvantages to hot working:

Advantages of Hot Working | Disadvantages of Cold Working |

|---|---|

Requires a lot less force | Poorer control of the final dimension |

Impose more heavy deformation per pass breaking down coarse structures into finer ones with more consistent, superior properties. | Poor surface due to oxidation of alloy, which may require pickling to remove |

Can better seal up internal defects such as cracks and pores (diffusion bonding) and reduce chemical segregation (coring). | Possibility to pick up gases in metal in some cases, leading to embrittlement or internal oxidation (e.g. firestain in silver) |

Must heat up metal uniformly before working (expensive, slow, needs equipment) |

In jewelry, cold working is often preferred because:

Better control of final shape, dimensions, and deformation pattern

Ability to work harden alloy, improving service behavior of jewelry

Better control of the surface quality of the item

However, when cold working, it is necessary to remember to anneal and maintain equipment to the standard necessary for the quality (e.g. roll surface dressing, etc.).

Key points

The key points are as follows:

An as-cast alloy can have an undesirable shape and properties, thereby requiring further work.

When we deform the alloy at room temperature, it becomes harder and more brittle. Annealing is necessary to avoid cracking (overworking).

The microstructure is heavily dependent upon the amount of work and the temperature and time of annealing.

It is preferable to work the alloy when hot for extensive shaping so the microstructure recrystallizes during the deformation. This is known as hot working.

For hardening the material, cold working is best.

Comments